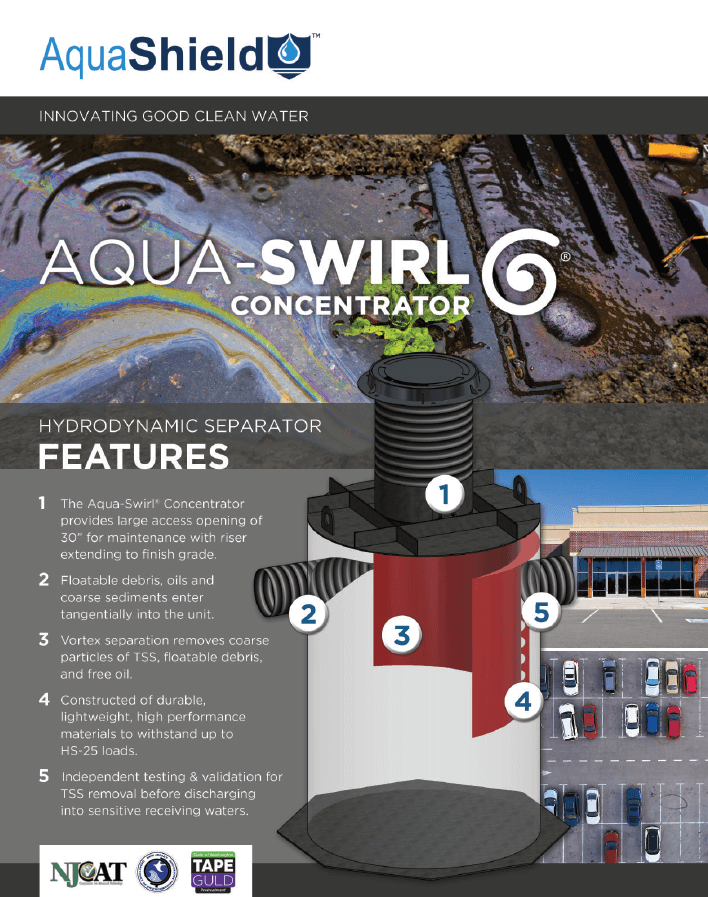

|

AquaShield, a Komline Company

2733 Kanasita Drive, Suite 111 Chattanooga, TN 37343 Toll Free: 888.344.9044 | Phone: 423.870.8888 © 2000-2024 AquaShield™. All Rights Reserved. |

VISION STATEMENT

To be the vanguard for providing technology that gives higher quality usable water to every country and community that needs it.