Go-Filter: Operations

The Go-Filter™ is designed to provide a high level of turbidity reduction through the use of a gross pollutant separator and strainer for pretreatment followed by two cross-flow (centrifugal) sand filters configured in parallel. When compared to traditional sand filters, the Go-Filter™ achieves high performance efficiency using cross-flow filtration technology by maximizing contact time between the suspended sediment and the silica based sand filter media. This radial cross-flow design traps particles at the surface of the media bed instead of deep within a media bed such as a traditional sand filter. This allows the Go-Filter™ technology to use 50% less water for backwashing than traditional filters. Backwashing is accomplished using much less time and energy than conventional sand filters.

Traditional sand filters rely on forcing suspended particles deep into the media bed to improve sediment removal efficiency; hence, its ability to transmit water is diminished with increasing particle loading. This decreased flow capacity results in increased difficulty for backwashing since more water, time and energy is needed to remove the trapped material. While studies show that traditional sand filters can remove particles down to approximately 10 microns, high turbidity levels can still occur with increasing clay content (<1.5 microns) in the water. The Go-Filter™ technology achieves 95% solids removal to the submicron level, or 0.5 microns (0.0005 mm). This superior level of performance allows for clear water discharges from the Go-Filter™ Mobile Treatment System.

Traditional sand filters rely on forcing suspended particles deep into the media bed to improve sediment removal efficiency; hence, its ability to transmit water is diminished with increasing particle loading. This decreased flow capacity results in increased difficulty for backwashing since more water, time and energy is needed to remove the trapped material. While studies show that traditional sand filters can remove particles down to approximately 10 microns, high turbidity levels can still occur with increasing clay content (<1.5 microns) in the water. The Go-Filter™ technology achieves 95% solids removal to the submicron level, or 0.5 microns (0.0005 mm). This superior level of performance allows for clear water discharges from the Go-Filter™ Mobile Treatment System.

|

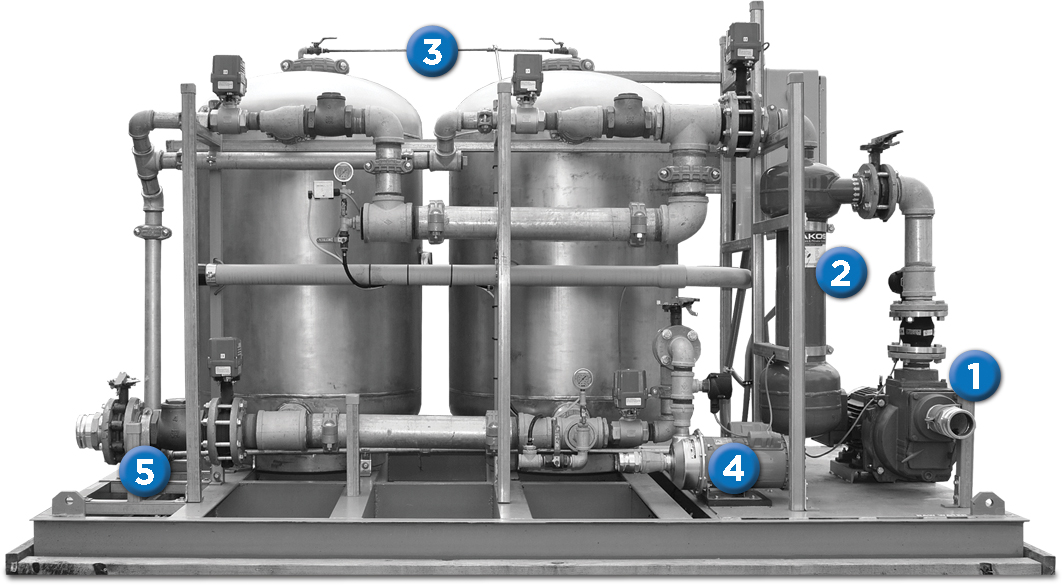

The Go-Filter™ treatment process is described in the following five steps (See figure 1):

Step 1. Water Supply and Flow Rate The skid mounted self priming trash pump conveys captured stormwater runoff from an adjacent collection pond or storage vessel at a flow rate up to 250 gallons per minute (gpm, or 16 liters per second, L/s). Since the Go-Filter™ can also treatment industrial wastewater, other means can be applied in order to direct water to the treatment system. Step 2. Pretreatment Pretreatment is accomplished at the selected flow rate when coarse materials are removed from the treatment flow through the use of a pollutant separator and strainer also positioned on the system’s trailer. Step 3. Primary Treatment Pretreated water continues at the selected flow rate to two cross-flow media beds configured in parallel on the trailer. Each filter consists of a 36-inch (91 cm) diameter stainless steel, ASME certified vessel. The filtration assembly also includes an automated control panel and associated switches, valves, strainers and tubing. Both the filtration assembly and trash pump are powered by a single connection using electricity or generator. Learn about our recommended media source, PathShield™, a chemical free, non toxic media effective at destroying coliform bacteria on contact and proven effective at flow rates of up to 20 gallons per minute. Step 4. Backwash Both cross-flow filters are self-cleaning through the use of backwashing cycles. Filter backwashing utilizes process water without the need for a dedicated water storage vessel. Backwash cycles are triggered automatically by pressure differentials resulting from particle accumulation within the filters and have typical durations of four to eight minutes. Step 5. Discharge Post-filtration (treated) water exits the filters under gravity flow through a flexible hose at the same flow rate of the trash pump. The discharge hose runs from the filter assembly to a designated discharge point away from the trailer. No additional treatment is necessary once water is discharged from the system. |

GO-FILTER, Figure 1

|