Recently, the St. Louis Metropolitan Sewer District approved the Aqua-Filter for General Use Level and for 80% TSS removal. There are no site application restrictions, and the Aqua-Filter can be used as a standalone device for new development or redevelopment sites of any size. These approvals were based on the NJDEP Certification, following the NJCAT field verification. If you have questions about how this product can solve your stormwater filtration needs, reach out to our experienced staff of engineers and specialists. We’re ready to help you spec any project and meet local, regional and statewide regulations. Find your local rep here. You can view the MSDs listings at http://www.stlmsd.com/what-we-do/stormwater-management/bmp-toolbox/technology-matrix/proprietary-bmps To find out if the Aqua-Filter could work for your next project, call us at 1-888-344-9044.

2 Comments

If you’re attending the TNSA East Tennessee Development Conference this month, you won’t want to miss our presentation to help explain how hydrodynamic separators can be part of a smart low impact development (LID) plan. As new regulations expand and more cities and counties prioritize the need to capture, infiltrate or store the first inch of rainfall, an HDS can help you provide a first line of treatment to preserve long term functionality of sensitive LID structures. You’ll get all the details in our session on Nov. 19, 1:55-2:45 p.m. in classroom 301-B. We'll also have a table top display, product information and our regional representative will be there to answer questions. Don't miss it! Not registered? It’s not too late! You can see a full agenda and sign-up at the Tennessee Stormwater Association’s website.  If you’re new to stormwater management or a professional with 30 years of experience, you are probably aware that 80% TSS removal efficiency is the key metric for getting designs approved, meeting regulation and showing that your design is a success. But the lack of an influent sediment particle size standard means that 80% ratings may not mean what you think it does. Check out the break down of these measurements and how the lack of a particulate definition means you may not be comparing apples to apples in your stormwater device review. The Importance of Particle Size Distribution (PSD) When Defining 80% TSS Removal Efficiency Stormwater management manuals often include design guidelines for manufactured treatment devices (MTDs) that include technologies such as hydrodynamic separation and filtration. Local jurisdictions may approve an MTD provided that testing demonstrates at least 80% TSS removal efficiency. However, this performance criterion lacks specification for an influent sediment particle size distribution (PSD) for either laboratory or field-testing programs. The critical role that test sediment PSD plays in MTD performance testing is essential, and those gradations affect TSS removal efficiency for both annual and per storm event sizing. A laboratory hydrodynamic separator (HDS) performance curve is compared to a series of performance curves calculated using the Peclet Number for the same tested device based on median (d50) values ranging from 45 to 125 microns. These performance curves can also be used to size an HDS based on both an annual and per storm event basis. A number of consequences result from excluding a PSD specification for MTDs. While undersized MTDs may exhibit diminished performance for TSS removal efficiency, they can also cause concern for functionality and flow-through conveyance for undersized piping. Undersized facilities may also experience increased maintenance frequency and associated costs due to decreased storage capacity. While oversizing may provide a conservative treatment approach, it (a) increases a system’s footprint including any bypass structures, (b) may limit options for limited space and retrofit installations, and (c) increases project costs. To learn more, check out our presentation on SlideShare. You may also be interested in reading: How Manufactured Treatment Devices (MTDs) Tackle Different Soil Types. Tell us what you think about the TSS Removal Efficiency Standard in the comments!  AquaShield is proud to announce that our very own Mark Miller will be making a presentation at the Tennessee Stormwater Association’s Annual Conference happening Oct. 20-22. This year’s theme is “Fall Into Green” and will address the challenges and solutions for stormwater management in Tennessee. The best part is the location, the beautiful Fall Creek Falls State Park in Pikeville, Tennessee. Don’t miss it! In this presentation we will explore the importance of particle size distribution when defining 80% TSS removal efficiency. The predictive performance scaling method for hydrodynamic separators (HDS) using the Peclet number is used to size HDS for different particle sizes. Consequences for undersizing and oversizing HDS systems are also explained. Using this method can save you frustration and time, allowing more accurate assessment of HDS devices. Mark your calendar for Oct. 22 at 3:15 p.m. so you won’t miss this presentation. We will also have a table. Stop by and check out our information! You can still register for the conference at the Tennessee Stormwater Association’s website.  There are clear impacts of failed stormwater management programs – erosion, polluted waterways and even damage to drinking water. For some projects, a single solution is not enough to protect sensitive waterways from runoff. The treatment train approach is an increasingly important management tool engineers can consider for challenging projects. So what exactly is a treatment train system? According to a report from Ecological Engineering, it is a model that is “capable of predicting the performance of stormwater wetlands, ponds, vegetated swales, sediment basins and biofilters, with a single algorithm. The model describes two principal processes: (a) water quality behavior and (b) hydrodynamic behavior.”[i] To put it simply, it’s creating a stormwater management plan with a series of BMPs that often combines natural treatment (such as a pond or grass filter) with a manufactured treatment device using hydrodynamic separation (such as the Aqua-Swirl). When should this model be considered? The treatment train model for stormwater management should be considered when sensitive water is at risk. According to the EPA, “Sand and organic filters are typically used as the second downstream component of a treatment train to remove pollution from stormwater before discharge to receiving waters, to groundwater, or for collection and reuse.”[ii] Hydrodynamic separation provides the upstream pretreatment component of the treatment train. Can a treatment train be considered if a pond or grass filter isn’t an option due to location / space? Yes! Significant operational and performance benefits can be realized through the use of the treatment train design that is incorporated into the Aqua-FilterTM Stormwater Filtration System as documented by long-term independent field-testing of a system. This included the Aqua-Swirl hydrodynamic separator as the upstream (pretreatment) component followed by a filtration chamber as the downstream (secondary) component. The Aqua-Swirl is designed to remove sediment, debris, floatables and free-floating oil, while the filtration chamber refines and polishes the stormwater quality prior to discharge by removing fine-grained particles. Over 90% of suspended sediment removal is provided by the Aqua-Filter on a net annual basis against fine-grained particulate. The treatment train serves to provide exceptional sediment removal including the fine-grained particulate at a loading rate up to 21 gpm/ft2. Benefits Achieved: The Aqua-Filter system design provides the following benefits for the treatment of stormwater runoff as opposed to filtration systems that rely solely on filtration and do not incorporate pretreatment:

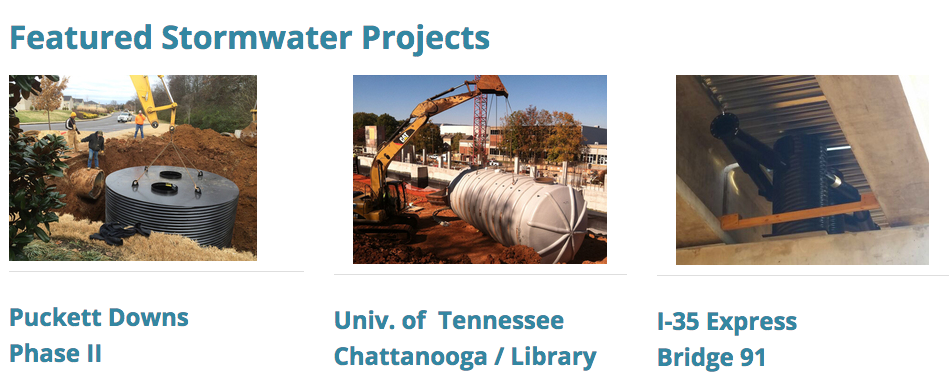

See a complete breakdown of the outcomes in our Tech Report. Not sure if a Treatment Train could work for you? Register for our FREE stormwater consultation to discuss the technicalities of your treatment plan. [i] “Modelling Urban Stormwater Treatment – A Unified Approach.” Tony H.F. Wong, Tim D. Fletcher, Hugh P. Duncah. http://www.researchgate.net/publication/22242979 [ii] “Stormwater Management Best Practices” EPB.gov. http://www.epa.gov/greeningepa/stormwater/best_practices.htm The team at AquaShield is proud to demonstrate how our integrated stormwater solutions can solve complex stormwater problems and meet stringent LID requirements. Take a few minutes to view the new photos and feature projects on our website. You'll get details on recent projects and see just a few of the states we've recently worked in. You'll also be able to read quotes from engineers and installation contractors. If you have a stormwater problem, we can help! Don't see a problem similar to yours? We're always looking for new challenges! Give us a call to see how your project can be our next stormwater case study. We’re very excited to be at StormCon 2015 as a presenter but also in the Exhibit Hall at booth #100! Come by our booth for more information about how AquaShield can help solve your stormwater problems with integrated products and earth friendly, LID solutions. Don’t forget to ask us about our new filtration options!

If you’re in the Austin area but didn’t purchase tickets to StormCon, you can still visit our booth! Just email our marketing team at [email protected] and request your email pass to access the exhibit hall as our guest August 2 to 6. If you are attending StormCon, don’t miss our presentation. We will explore the predictive performance scaling method for hydrodynamic separators using the Peclet number. Put us on your schedule for August 5, Room 53 from 11-11:30 a.m. We’ll see you there!  We know our audience is well educated about stormwater filtration systems, when regulation calls for them, and how they should be used and installed. But every year at trade shows and lunch and learn presentations, we are surprised to find out how many engineers don’t know about some benefits offered by the Aqua-Filter. Here are a few to check out. 1. If it’s installed in the USA, it’s built in the USA. That’s right; the Aqua-Filter is built at home, as close to the installation state as possible. This allows us to deliver the product faster and more cost efficiently. 2. Installing the Aqua-Filter doesn’t require a crane. The modular construction and lightweight but durable materials mean skipping the high cost of a crane. 3. As a bonus, the installation doesn’t require special sealants for piping connections. 4. Each unit includes lifting supports and stub-outs for the inlet and outlet piping to allow for quick and simple connections. 5. A dual process, with vortex separation removing larger pollutants prior to the water reaching the filtration chamber, extends the life of the filter media and reduces maintenance requirements. 6. Independent validation should always be considered. Options include the new Total Phosphorus Removal Credit from the Virginia Department of Environmental Quality, along with NJDEP certification and NJCAT verification. The Aqua-Filter has independent field test verification and total Phosphorus Removal Credit from Virginia. 7. What storage is included for sediment? What about oil and debris? This number can help you consider the long-term cost of maintenance. The Aqua-Filter has sediment storage of up to 310 ft3 and oil and debris storage up to 1,900 gallons. 8. The Aqua-Filter works with the only EPA registered filter media for stormwater treatment. PathShield filter media offers a new approach to water treatment by killing bacteria when it comes into contact with filter media granules. The filter media is stable, non-toxic, not consumed, non-corrosive, requires no power source to kill bacteria, and is not affected by temperature changes. 9. The Aqua-Filter can be customized to work with your project. You can start with our project and system design tool at or call us to speak with our experienced, technical team of experts. You might also like to read our comparison between NJDEP and NJCAT. When considering a stormwater filtration system, engineers have an array of choices. So, it’s important to first consider these short and long-term outcomes and options when drafting a project’s specifications.

1. What flow rates are available with the system? This can vary widely. At first glance it may appear that the highest flow rate is the best; after all, it can better handle high water rates in storms and floods. However, it’s not that simple, which leads us to the next question. 2. 80 percent removal of what? Too often, stormwater filtration systems are not tested consistently, lacking apples to apples comparisons. This leads to challenges for engineers trying to meet regulations that can differ broadly across the country. The specs may state that a filtration device meets the 80% removal rate, but if lab testing relied on a larger particle size than another system, you might not be getting the whole picture. Make sure you ask about the particle size that was used in the product’s testing to confirm that it meets your desired filtration expectations. Don’t skip out on quality just to achieve a higher flow rate. 3. What field tests were used? Best-case scenario is to select a product that has been tested by a third party, outside the lab under real world conditions. Stormwater runoff contains all sorts of material from tree branches, to sediment to car oil. Product performance can’t truly be measured by lab testing alone. 4. What are the installation requirements? Engineers walk a tightrope while juggling installation timelines, client demands and budgets. Ask early about what equipment will be required for installation, especially if special circumstances exist. Will shipping require road closures? How long until it is ready? What about backfilling? 5. What are the storage capabilities? Compare the sediment storage as well as the oil and debris storage, then consider what this means for maintenance and long-term life of the equipment. Can your client save more over 5 years by investing now? 6. What filter media options are available to my client? Take the time to ask extra questions about the filter media, how easy is it to use, what filter options are available for site-specific contaminants of concern, and how often it requires replacement. By analyzing the stormwater filtration system up front, engineers can bring added value to their clients by helping address concerns before they happen, and helping achieve progressive stormwater management for the long term. Do you have questions? Reach out to us to discuss your stormwater filtration needs. We’re ready to answer your toughest questions. Merrillville Receives CLEAN Community designation for Progressive Stormwater Management Plan7/2/2015 The AquaShield team was thrilled to see that Merrillville, Indiana was recently recognized for its focus on environmental matters. We have lots of Aqua-Swirls in and around the region and we're proud to see recognition of how communities in Indiana are effectively contributing to good clean water with progressive stormwater management plans.

MERRILLVILLE | The town was recognized Tuesday for its focus on environmental matters. The Indiana Department of Environmental Management has designated Merrillville as a Comprehensive Local Environmental Action Network Community...Multiple town departments, including the Stormwater Utility, parks department and public works, are collaborating to achieve the goals. Read the article on nwi.com. Thinking about your own stormwater management plan? Learn more about our offerings. |

AuthorAquaShield staff keeping you up to date on the latest in stormwater solutions. Archives

December 2015

Categories

All

|

|

AquaShield, a Komline Company

2733 Kanasita Drive, Suite 111 Chattanooga, TN 37343 Toll Free: 888.344.9044 | Phone: 423.870.8888 © 2000-2024 AquaShield™. All Rights Reserved. |

VISION STATEMENT

To be the vanguard for providing technology that gives higher quality usable water to every country and community that needs it.

RSS Feed

RSS Feed